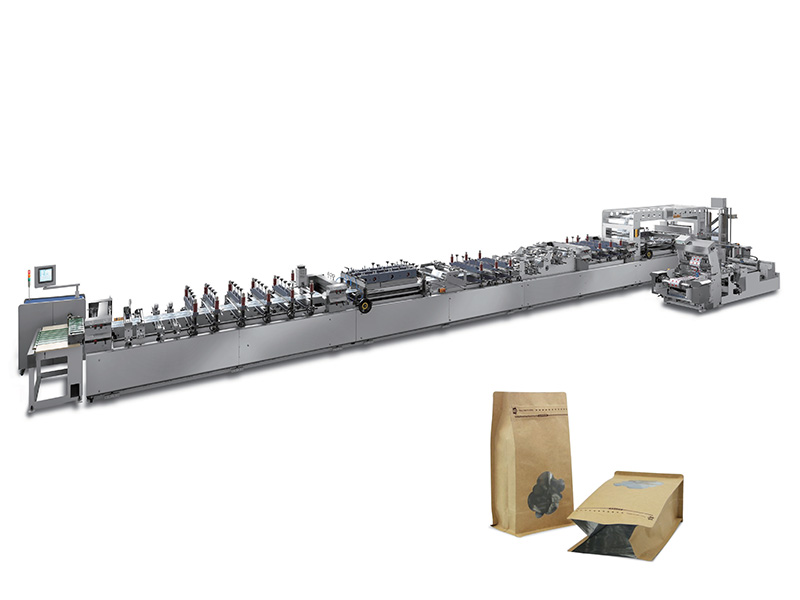

The bottom seal bag making machine is a state-of-the-art piece of equipment designed to optimize the production process for high-quality bags. This machine incorporates advanced automation, precise control systems, and efficient material handling, ensuring that manufacturers can produce bags with speed, accuracy, and consistency.

Key Features of the Bottom Seal Bag Making Machine

Automatic Synchronization and Tension Control: The bottom seal bag making machine is equipped with an automatic synchronization and tension control system, which helps maintain consistent tension throughout the production process. This reduces material waste and ensures smooth, uninterrupted operation.

PLC Automatic Routing System: A PLC-controlled system manages the routing and various operational logic states of the bottom seal bag maker, providing precise control over production. This automation allows for greater accuracy in bag dimensions and sealing, resulting in high-quality output.

Barrier-Impaired Diagnostic System: The machine features a diagnostic system that identifies and alerts operators to potential mechanical issues. This proactive approach helps minimize downtime and ensures the bottom seal bag machine operates efficiently.

Pneumatic Shaft for Nureeling: Using a pneumatic shaft during nureeling improves stability and enhances the overall performance of the bottom seal bag making machine, resulting in smoother operation and longer-lasting components.

Servo Motor for Horizontal Material Feeding: One of the standout features of this bag-making machine is its servo motor-driven horizontal feeding system, which ensures precise feeding lengths. This level of control helps achieve consistent bag sizes, critical for uniform production.

Mechanical Hot Press: Unlike traditional vapor-action systems, this bottom seal bag making machine uses a mechanical movement for the hot press, avoiding the disadvantages of vapor-based systems like instability and shortened equipment life. This ensures greater reliability and efficiency in the production process.

Quick and Smooth Feeding: The machine is designed to feed materials quickly and smoothly, which speeds up the production process and increases output. This makes the bottom seal bag making equipment ideal for high-volume production environments.

Aesthetic and Functional Benefits

Aesthetically Pleasing Sample Bags: The bottom seal bag making machine is capable of producing sample bags that not only meet high functional standards but also have an aesthetically pleasing appearance. This is particularly important for businesses that prioritize both quality and design in their packaging.

Exclusive Manufacturer in China: As the sole manufacturer in China specializing in this type of bottom seal bag making equipment, our company leads the market with its unique expertise and commitment to quality.

Advantages of Using a Bottom Seal Bag Making Machine

Increased Production Efficiency: The advanced automation and precision control systems of the bottom seal bag making machine allow manufacturers to produce bags faster and with fewer errors, boosting overall productivity.

Enhanced Machine Durability: The incorporation of durable components, such as the pneumatic shaft and mechanical hot press, ensures that the bottom seal bag machine has a long operational life, reducing maintenance costs and increasing return on investment.

Customizable Production: This bag-making machine offers customizable settings, allowing manufacturers to adjust for various bag sizes, materials, and production speeds to meet specific business needs.

This bottom seal bag making machine is an essential piece of equipment for businesses seeking to improve their bag production process. With its innovative features, reliable performance, and ability to produce aesthetically appealing bags, this machine is a leader in the bottom seal bag manufacturing industry. Contact us for more details.